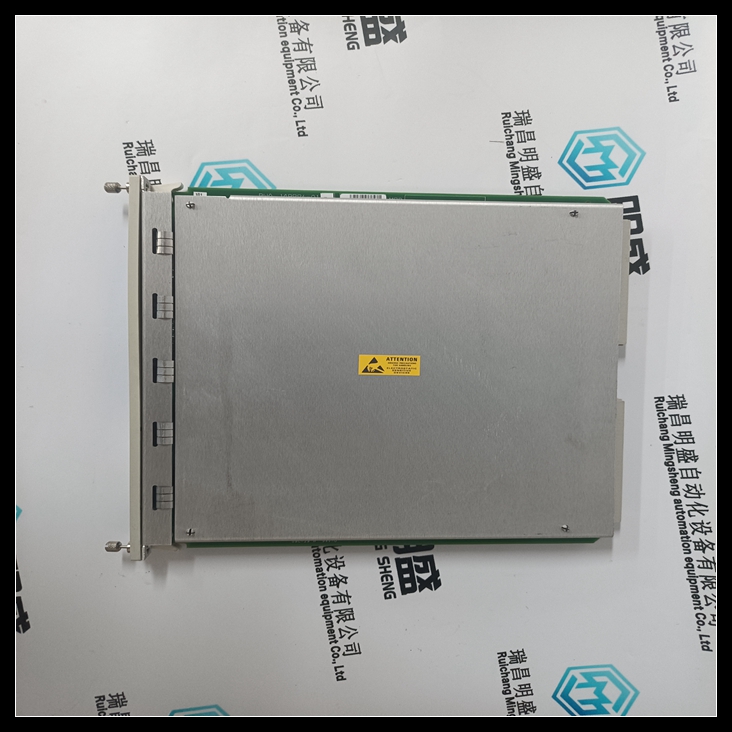

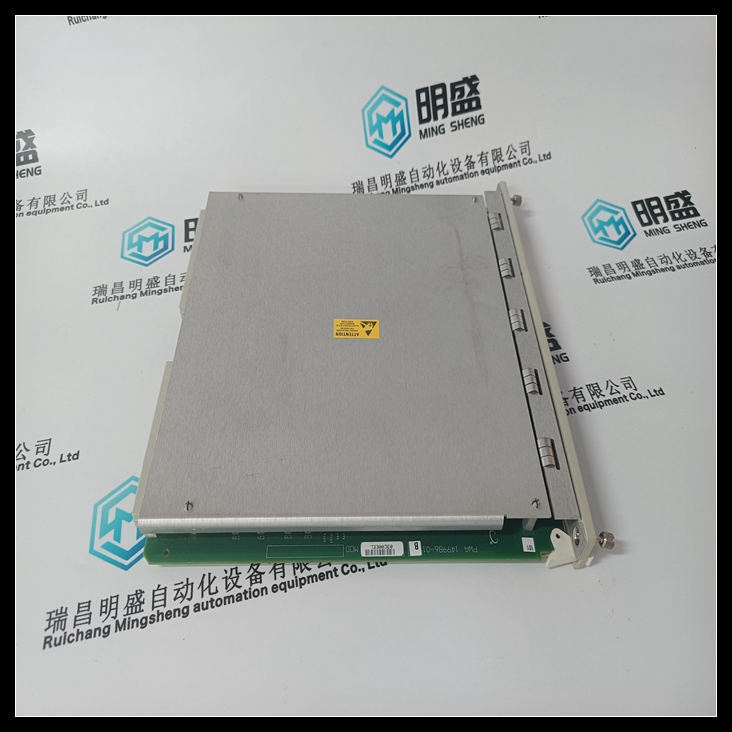

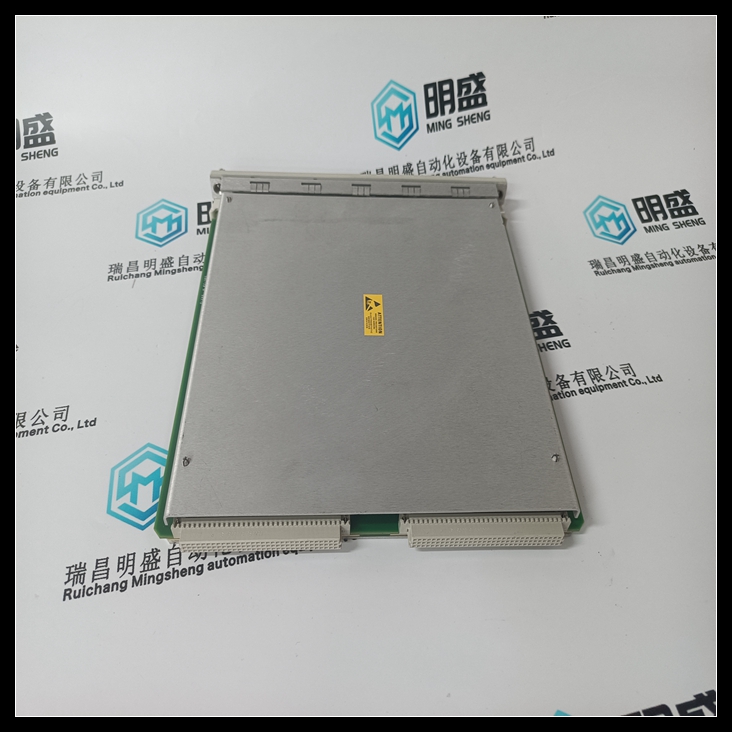

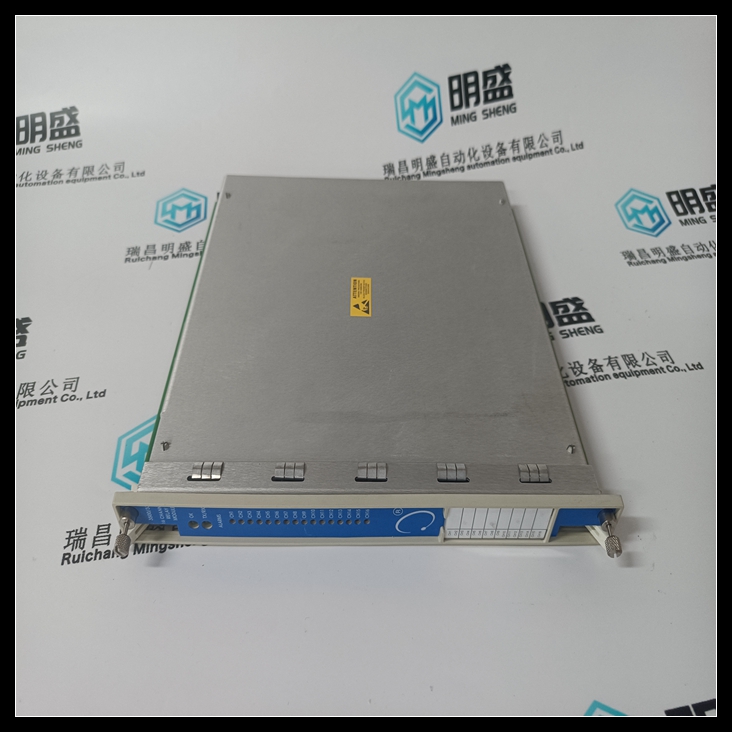

BENTLY 3500/33 149986-01工控處理器模塊庫存

類目:RELIANCE

型號:3500/33 149986-01

全國服務(wù)熱線:15270269218

手機:15270269218

微信:15270269218

QQ:3136378118

Email:3136378118@qq.com