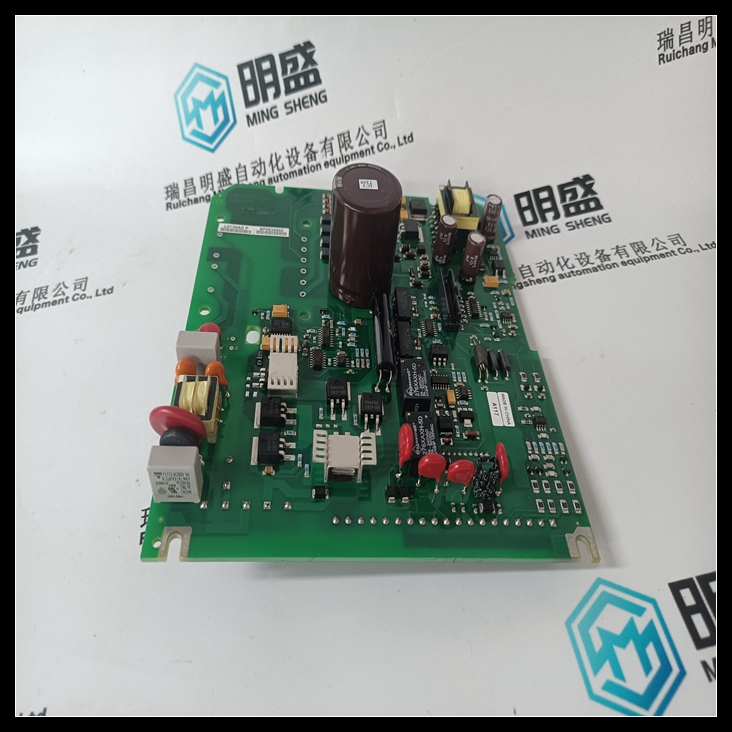

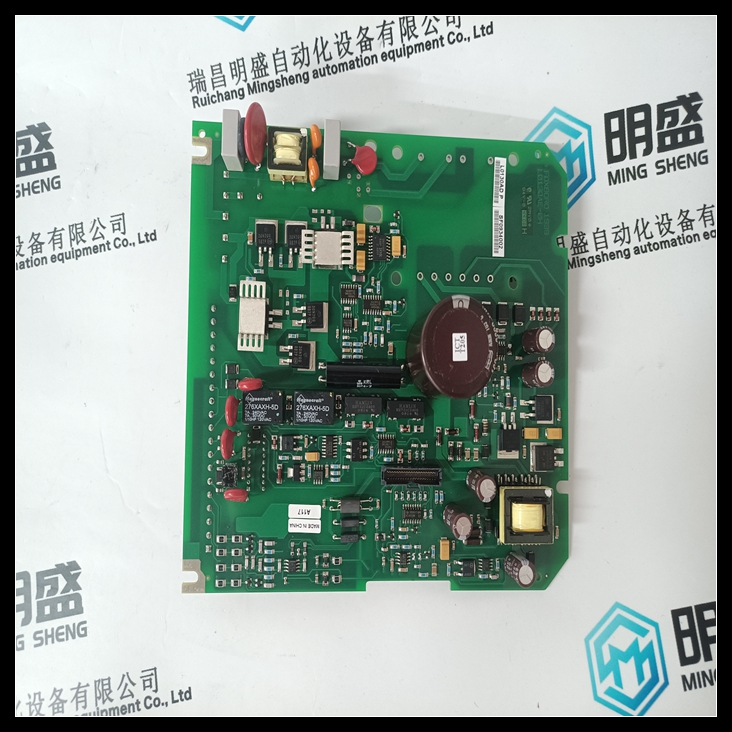

L0130AE-0H脈沖輸入通道模塊

類目:RELIANCE

型號:L0130AE-0H

全國服務(wù)熱線:15270269218

手機(jī):15270269218

微信:15270269218

QQ:3136378118

Email:3136378118@qq.com